This story begins with my search to find a “Gentlemen’s Folder.” If you’ve never heard the term, a Gentlemen’s Folder is a slim, elegant folding knife that you carry every day, but is fancy enough for special occasions. These are usually high-quality knives that use natural handle materials like polished bone or exotic hardwoods. It’s the kind of knife your children inherit when you’re gone.

But such knives are often expensive. And I’m thrifty when it comes to gear. I’m willing to pay more for quality. But I need to know I’ll enjoy using it for many years to come.

Secret Desires

My search for a gentlemen’s folder began and ended with the Fallkniven TK3 folding knife. If you’ve read my review of the Fallkniven F1 survival knife, then you know how much I love that knife and respect the Fallkniven brand.

So it was natural that I looked to Fallkniven to supply my “Gentlemen’s Folder.” And it didn’t hurt that I saw Ray Mears, a respected bushcraft instructor, use it in one of his fine videos.

By the Numbers

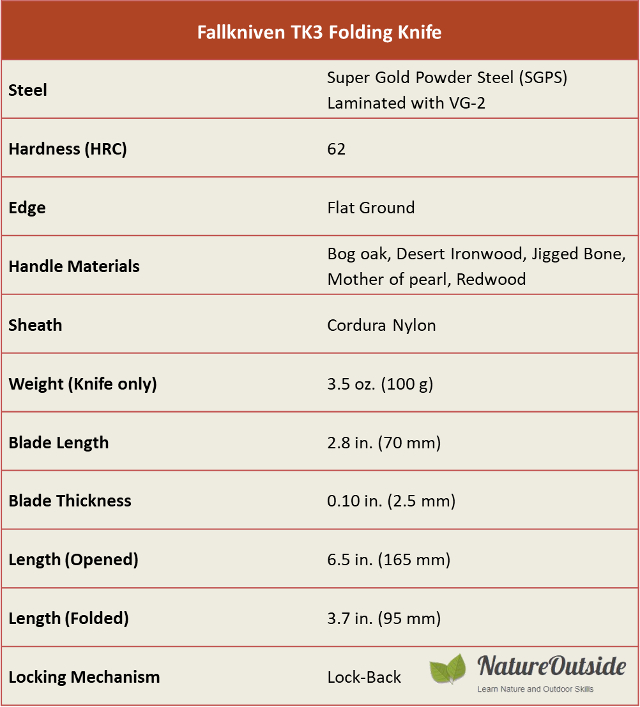

Here are the specifications for the TK3:

Fallkniven TK3 Specifications

As you can see, the knife is made with high quality materials. My understanding is that it is designed in Sweden, but manufactured in Seki City, Japan.

Taking the Plunge

Whenever you buy expensive gear (or anything for that matter), you take a leap of faith. And purchasing a brand with Fallkniven’s stellar reputation goes a long way toward assuaging any doubts.

The model I liked best had Desert Ironwood scales. I loved the idea of having a Fallkniven made with a beautiful and durable handle material that is native to California, my home. At the time of this writing, the MSRP for this model is $287.10.

So I placed my order with a reputable vendor in the United States and started counting the days. I fell asleep each night dreaming about carrying this small Cadillac in my pocket.

Little did I know the disappointment headed my way.

Bitter Disappointment

I can barely contain myself when the knife arrives. It comes in a wooden box, which I open with great reverence.

I ordered the Desert Ironwood handle. And while not the best ironwood I’ve seen, it is handsome and fitted with precision. The mechanism is wonderful and the blade is well centered. It deploys smoothly and I without any gaps or blade play. Wonderful!

But when I examine the blade, I know there is trouble.

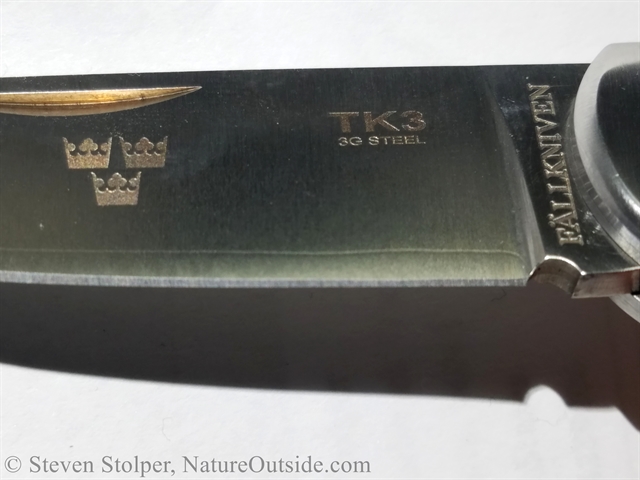

Uneven Lamination

The knife is laminated (VG2-SGPS-VG2). And the lamination lines are very different on each side of the blade. On one side, the lamination line is approximate 3 mm from the edge. It runs parallel to the edge until it meets the spine near the tip. This is what I expect.

But on the other side, the lamination line is approximately 5 mm from the edge. It runs parallel to the edge. But near the tip, it curves outward toward the tip and does not meet the spine.

Left lamination line. This is what I expect

Right lamination line. It is much farther from the edge. Near the tip, it curves to the point instead of meeting the spine.

A small difference in the lamination lines is no big deal. But this is different from my F1, where both lamination lines are identical. I’m more concerned that one of the lamination lines does not reach the spine, but instead turns 90 degrees toward the tip.

So I Emailed Fallkniven. Here is their reply:

… The final step in using laminate blades is that only when the blade is fully polished we discover where the lamination lines are. Faulty blades are always rejected but blades are kept as we consider this as a cosmetic detail with no negative effect on the blade performance. Should we use only 100 % perfect blades, our knives would become extremely expensive.

– Fällkniven AB

Is this explanation correct? Is it purely cosmetic, or will it affect the performance and durability of my knife?

I posed the question on a couple of Internet forums. The answers I received fell into three categories.

1. It’s Just Cosmetic

A small group responded that the answer I received from Fallkniven made sense. Here are a few of the replies. It addresses my concern about the VG-2 curving to the point.

I understand your disappointment. I believe their explanation. If you were to grind the spine until the lam line met, or grind off some of the VG2 overlay on the offending side until the line moved to where you wanted it- either, I think, would “fix” it.

But you don’t need to do either. The good stuff is still in there. There is just a smudge of extra VG2 covering it at the tip- that’s how I see it anyway.

Another reply in a similar vein.

The distance from edge to lamination line is cosmetic, and will not make any difference to the performance of the knife. If the core steel forms the cutting edge, that is what matters, and that is what Fallkniven are going to look at for quality control. The little swoop at the tip would bother me more than the distance up from the edge, but if it cuts, and that tip doesn’t go blunt fast, then I would say that the right steel is in the right place, and you can stop worrying.

… Further more, people have been pointing out this exact same issue, on Fallkniven folders, for at least eight years, and apparently Fallkniven have been giving pretty much the same answer for all that time. Over that time, have there been lots of people trashing the knives on line because they do not perform?

This is the answer I wanted to believe. But there were other opinions.

2. It’s a Real Problem

The most disturbing response was that the knife was ground off-center. And that the unevenness of the VG-2 was the result. What this means is that the layers of VG-2 are uneven, and not up to the maker’s specifications.

The outer steel layer is thinner on one side than on the other. If they say it does not matter, why do they laminate the steel?

I think this is a serious manufacturing fault. As the knives are made in Japan, I would expect perfection. As they are very expensive, I would expect and demand perfection.

And another opinion:

The steels they made the blades from are supplied to very, very precise measurements. If there is a known problem with the centering of the grinding of the fused /laminated blade, that points to a problem in the production.

QC should pick this up.

… If the thickness of the softer cladding does not matter, why is it there for a start? These blades are in principle a composite material.

This answer makes sense to me. The cladding is there for a reason. And not having it in the proper thickness is more than just a cosmetic issue.

3. You Paid for Higher Quality

A third opinion argues that I paid for a high quality product. And for that price, I should hold the knife to a higher standard than “it still cuts.”

I think the explanation they gave you is probably correct but if you are unhappy with the cosmetics you will have a tough time being completely happy with the knife. That lamination line will always be other than you wanted.

Assuming you can return it I would do so.

Another opinion along the same lines.

I am in that crowd, the ones who think on a plus $200 knife the lamination steel should be a lot better… I would send it back and tell them to send you one that is correctly ground or send your money back.

Uneven Grind

I was disturbed by the thought that the knife was ground unevenly, and that the VG-2 layers may not be up to spec. So I examined the edge of my knife and received an unpleasant surprise.

I noticed an additional irregularity at the base of the blade. On one side, the edge is uniform. On the other, it appears “pinched” at the base of the blade (I don’t know the right term). To me, this indicates the blade is just not ground well.

Here is the good side. The edge is uniform near the base of the blade:

The left edge of the blade appears normal

On the other side, the edge is “pinched” toward the base of the blade. Here are two photographs:

A view of the right edge of the blade. Notice how the grind narrows toward the base.

A closer look at the grind at the base of the blade.

Most people had an opinion like these.

Steven that is not an acceptable edge on a new knife. It could be sharpened out easily but this knife should never have been sold with an edge grind like that, at least it is not something I would accept.

And another.

Personally I would demand a new knife. The edge problem is a minor thing, easy to fix next time you sharpen it, but considering their reputation and cost, should have been perfect in all aspects.

If you google ’Fällkniven’ the first site that comes up is Fällknivens own, telling you ’The best knives in the world!’

I want to express my appreciation for all the helpful comments I received when I asked for help on these forums (BushcraftUK and Blades and Bushlore).

Attempt to Exchange

The combination of uneven lamination and poor grind was enough to convince me that there was a problem with the knife. I decided to return it to the vendor (at my cost).

I still hadn’t given up on Fallkniven. So I asked for a replacement. But I also asked the vendor to inspect the new knife before they sent it to me. I eventually heard back from the vendor:

Hi Steven,

I have checked our remaining stock of this model, and unfortunately it is not of any better quality. I am assuming this is just an issue with this particular model. The grinds are uneven, and the lamination lines are worse than the one you returned. I just need your confirmation to issue the refund, instead of an exchange.

This seems to be a systematic problem with Fallkniven TK3 knives. My hopes of owning one are dashed.

I agree to the refund, but lose money on the transaction. Besides paying for the return shipping, the vendor chose to charge me for the original shipping because I returned the blade. Most retailers would not have done this, as I was returning defective merchandise. So I will keep this return policy in mind when I make my next knife purchase.

Not Recommended

I do not recommend the Fallkniven TK3. I had high hopes. But this knife is ultimately doomed by poor quality control.

And it turns out my experience wasn’t unique. I did further research and found posts on forums from others who experienced quality control problems with the TK3. The YouTube videos I watched prior to my purchase failed to mention this. And that is what motivated me to write this review.

So my search continues for a Gentlemen’s Folder. If you have good recommendations, please leave them in the comments, below.

Related Articles on NatureOutside

Bushcraft Knife Safety – 9 Tips to Avoid Accidents

For fun facts and useful tips, join the free Bushcraft Newsletter.

I cannot believe that you cannot understand that the thickness of the metals used is the exact same, but the way it’s ground is why the one side looks to be thinner than the other. They get blank stock that has the exact same thickness of the metals that are sandwiched together, with the outer layers that are perfectly milled to be the exact same thickness.

It is in the way the grind is done that exposes the appearance that the thickness isn’t the same throughout the material being ground. If you grind more material off of one side than the other, the lamination lines will expose more of the core material on that side. The sides have to have the exact same angle ground down to have the same revel exposed of the core. Since the Fallkniven knives have a convex grind, and they are typically finished by hand, they will inevitably have some small variations of exposure differences of the core material on each side. It would have to be very precise of a grind to be the same exposure on each side.

Thank you for your comment Dave. As you suggest, this knife has a poor grind. There is much less of the outer material on one side of the blade than the other. And as the article mentions, the grind is uneven to the point that the cutting edge geometry was asymmetric. This is not a small variation.

As a coda, I eventually obtained a very fine knife from a different manufacturer. It did not have any problems like the Fallkniven did, and I am very happy with it.

There were no “problems” with the Fallkniven knife you purchased. You didn’t get a 3G knife from any other manufacturer. I truly believe that you are splitting hairs over a minor issue here. My TK3 MOP has almost identical lamination lines on both sides of the blade. I also have a U2 with the same thing, almost identical lamination exposure.

Perhaps knife purchasing isn’t your “thing”. Have you ever thought of that? 😉

Dave, I don’t think I’m splitting hairs. Like you, I own (and love) several Fallkniven knives. None of them have uneven lamination to this extent or a grind that is so uneven. I also own laminated knives from several lesser-known makers. None have what I perceive as the workmanship issues with the TK3. I believe my quality standards are reasonable for a knife of this price.

The vendor was unable to supply another knife from his stock because they also found similar issues with their other knives. And I have since heard hearsay that this is a known “Fallkniven TK3 thing.”

Others may be happy to accept what I judge to be low quality. That is perfectly fine. But I am quite comfortable with my conclusion.

I am trying to locate a Fallkniven Cowry x blank of defective blade, anyone any ideas?

I am in the UK, i wish to make my own knife.

Graham, unfortunately I don’t know how to locate a Cowry blank. Good luck with your search.